lines, areas and volumes on site in a format that is easily ingested by InfoTech’s Appia software.

Image Courtesy of Leica Geosystems

Image Courtesy of Leica Geosystems

While there have been advances in bringing more digital tools to the construction field in some sectors, much of heavy civil construction still lags behind. Inspections and other documentation of as-builts are often still captured on pen and paper, to be entered into computer systems later in the day. This disconnect can lead to errors and delays on road projects, says Shawn Tinkey, field representative with HNTB.

“We were used to taking several measurements out in the field, and then going back to the office to draw out the lines [in CAD software], and if there was undulating surfaces we needed to create terrain models,” he says. Tinkey wasn’t satisfied with the GNSS and GPS survey software available, saying it was geared for professional surveyors, with too steep a learning curve for his field team to use properly. So he reached out internally to HNTB’s technology team, which led him to survey technology manufacturer Leica Geosystems and software maker InfoTech.

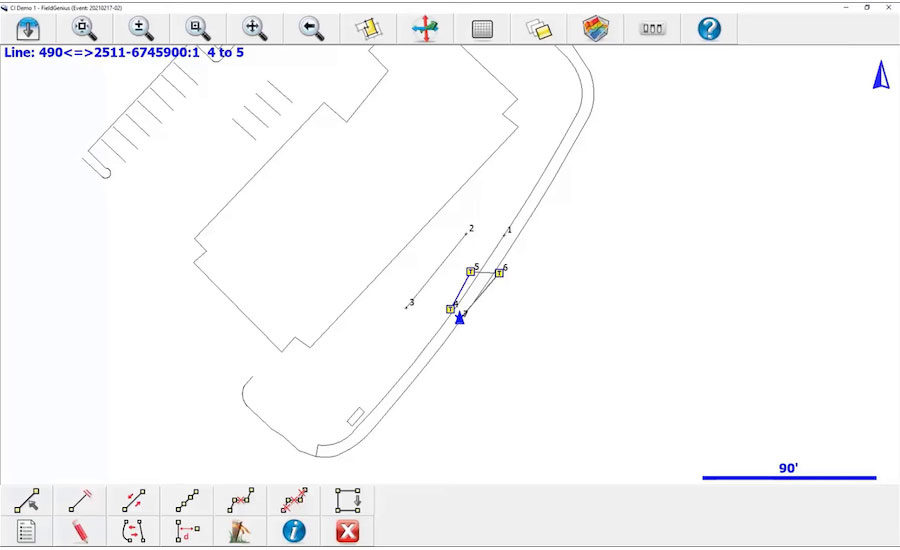

These conversations led to the two vendors’ latest collaboration, FieldGenius for Construction Inspection. This new software loads onto a standard tablet and can pair with a Leica GNSS rover. It’s designed to capture measurements on a road project using the units and formats expected by the submission forms in InfoTech’s Appia, the program of choice among many DOTs for their submissions and auditing. Field data is recorded and automatically populated into the system, eliminating the chance of transcription errors during data re-entry.

“It’s this idea of stake-less job inspections, which is becoming more common on larger road projects,” explains Kerry Trivers, vice president of marketing for Hexagon Geosystems U.S. and Canada. Hexagon is the parent company of Leica Geosystems. “This can become part of their digital workflow. Stake-less job inspection is where the future is for highway road construction.”

Giving the inspectors on the road crew a single workflow that doesn’t require data re-entry was a key goal, says Trivers. “You start by opening Appia projects in FieldGenius, then work as you would normally on site, capturing lines, field locations and volumes,” she says. ”Then you go back to the office and can easily generate the one file you need to export directly into Appia.” FieldGenius is designed to work with any of Leica’s GNSS rovers.

“Historically a lot of that as-built data collection is not done until the end of the job,” says Chad Schafer, associate vice president for business development and sales at InfoTech, maker of Appia. “This will allow the inspector to capture the as-builts for the day.”

Appia is designed to meet the specific requirements of owners of transportation infrastructure, typically state transportation departments as well as federal and local agencies. Schafer says that having field collection tools that feed directly into these reports will help reduce the kind of discrepancies that can come up during regular audits. “Having all that information come in from the field really helps manage the project,” he says. “It’s about bringing the field and the office together.”

And the field-to-office data pipeline for FieldGenius isn’t just theoretical. Over the course of the development of the software, HNTB’s Tinkey has been piloting the workflow on a $200-million, 24-mile design-build roadway reconstruction project in south-central Michigan for MDOT. Over the course of three months earlier this spring, his team used FieldGenius to collect regular inspection data, alongside their more traditional, less-digital approach. The difference in performance was stark.

“The biggest dramatic change for me was completely eliminating the learning curve of using secondary CAD software,” says Tinkey. “That was days of training, costs associated with the software, with IT setting it all up. Those were immediate savings.” There was also a time savings, with an average of 15 minutes to an hour of time saved per pay item in the survey, he estimates.

“My guys used to have to learn two different systems: how to be inspectors and surveyors,” Tinkey says, noting that GNSS survey equipment and CAD software often required unit conversions and a lot of specialized knowledge to use effectively in tandem. “But [FieldGenius] is just another measuring tool, not a surveying tool. It takes the scariness out of it, and is very intuitive for them to use.” A 15-minute tutorial was enough to get his crew up and running on inspections, regardless of skill level, he adds.

FieldGenius also helped further down the road, as it can work with Google Earth, allowing for as-builts to be stitched together on satellite visualizations of the site. This saves time in the office as well, as finalizing a project and determining all of the correct pay values is a time-consuming process.

“On my large $200-million project, we have 50,000 ft of sewer to go in. That take one individual two months in the winter to go through and determine the correct pay for it,” says Tinkey. “This visualization [workflow] would shorten that to a couple of weeks. A big part of these [projects] is determining where people are paying for stuff.”

Origination: https://www.enr.com/articles/52458-inspection-tool-fieldgenius-aims-to-improve-workflows-for-civil-construction

Recent Comments